| Sign In | Join Free | My portofva.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My portofva.com |

|

Place of Origin : Henan, China

Shape : Brick

Material : Corundum

SiO2 Content (%) : International standard

Al2O3 Content (%) : 0-92

MgO Content (%) : International standard

CaO Content (%) : International standard

Refractoriness (Degree) : Common (1580°< Refractoriness< 1770°)

CrO Content (%) : 2-93

SiC Content (%) : International standard

Model Number : 3,12,30,60,85,90

Brand Name : Hongtai

Processing Service : Punching, Cutting, Moulding

Advantage : Chemical Stability

Product name : Chrome Bricks

Application : Industrial Furnaces

Color : White

Apparent porosity/% : 16%~18%

Cold Crush Strength : >80Mpa

Bulk Density(g/cm3) : 2.95-3.1g/cm3

Size : Customized Size

Usage : Furnace Liner

Name : high chrome brick

Packaging Details :

1.Pallet+Paper or Steel angle bead+Paper board +Plastic or Steel belt +Plastic film

(1)Wooden pallet size:Usually0.92*0.92m(standard brick),but 1*1m (special shape brick) at most,

(2)Load weight of each pallet:Usually 1.5-1.7Tons, max 2.0 Tons.

(3

Port : Tianjin, Qingdao or others

Supply Ability : 3000 Ton/Tons per Month

MOQ : 2 tons

Price : $3,000.00 - $15,000.00/tons

Bricks Industrial Like Open Hearth Furnace Chrome Brick

High chrome bricks are made of industrial grade chromium trioxide and alumina as the main raw materials, or introduce a small amount of zirconia, etc., after high temperature firing, the content of chrome trioxide is not less than 75%, chrome trioxide, alumina and Shaped refractory products with a total content of zirconia not less than 98%. It has excellent corrosion resistance, high compressive strength at room temperature, high strength at high temperature, excellent wear resistance, high refractoriness, excellent thermal shock resistance, and good volume stability at high temperatures.

High chrome bricks are divided into four grades according to the content of chrome trioxide: GGZ-75, GGZ-85, GGZ-90, GGZ-95. In the grades, G, G, Z- are the initials of the Chinese phonetic alphabet of Gao, chrome, and brick respectively, and the Arabic numerals are the mass fractions of chromium trioxide.

China refractory manufacturer low price high chrome brick for rock wool and glass fiber furnace

High chrome brick technical data:

| Item | HT-GG90 | HT-GG85 | HT-GG60 | HT-GG30 | HT-GG12 | HT-GG03 |

| Cr2O3 % | ≥93 | ≥86 | ≥60 | ≥30 | ≥12 | ≥3 |

| Al2O3 % | — | — | ≤38 | ≤68 | ≤80 | ≤90 |

| Fe2O3 % | — | — | ≤0.2 | ≤0.2 | ≤0.5 | ≤0.5 |

| Apparent porosity % | ≤17 | ≤17 | ≤14 | ≤16 | ≤18 | ≤16 |

| Bulk Density g/cm3 | ≥4.3 | ≥4.2 | ≥3.63 | ≥3.53 | ≥3.3 | ≥3.25 |

| Cold compressive strength, Mpa | ≥100 | ≥100 | ≥130 | ≥130 | ≥120 | ≥120 |

| Refractoriness under load °C,(0.2MPa,0.6%) | ≥1680 | ≥1670 | ≥1700 | ≥1700 | ≥1700 | ≥1700 |

| Linear change rate % (1600°C×3h) | ±0.2 | ±0.2 | ±0.2 | ±0.2 | ±0.2 | ±0.2 |

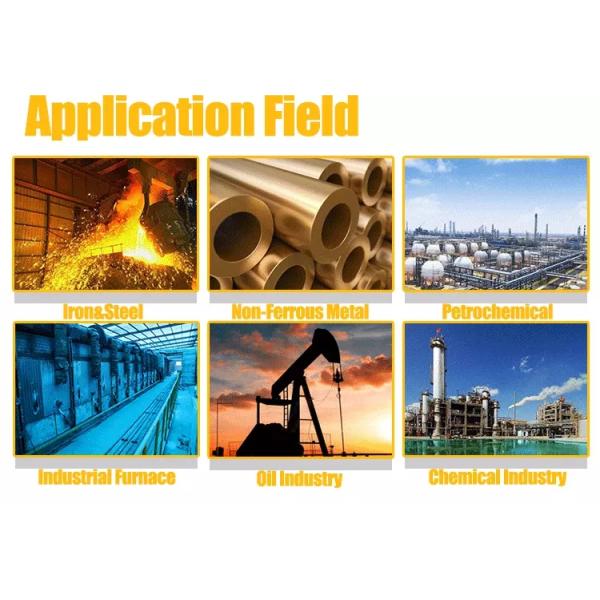

The raw material used in the high chrome series products is a solid solution synthesized by high-temperature melting of alumina and chromium oxide in a certain proportion. The production process of special refractory materials is used to make refractory bricks, which can improve and enhance the internal quality of the product and the high temperature performance of the product. It has the characteristics of high refractoriness, high strength, good thermal shock stability, and strong corrosion resistance. Erosion, abrasion resistance, corrosion resistance, and structural spalling resistance have been used in metallurgy, glass, carbon black, and petrochemical industries.

The cinder erosion resistance of High chrome brick

(1) The slag resistance of high chrome bricks. Coal melting is an acidic slag with a low melting point and is very corrosive to refractory materials. Both theory and practice show that high chromium bricks are refractory materials with good resistance to cinder erosion.

(2) With the increase of temperature, the viscosity of coal slag is greatly reduced.

(3) The large solubility of various refractory oxides in coal slag is lower than that of chrome oxide.

(4) Erosion rate of furnace lining. With the increase of chromium oxide content, the corrosion rate of the furnace lining decreases. The relationship between lining erosion rate and chromium oxide content.

(5) The anti-slag erosion rate of high chrome bricks with chrome oxide content of 60% ~ 90%.

In order to lower the melting point of coal slag and ensure the smooth production, the coal water slurry

A certain amount of lime (CaO) is added to the coal raw materials for the gasifier. Eventually, calcium oxide in the coal slag increases, and the corrosion resistance rate of high chromium bricks accelerates. The erosion rate of coal with different CaO content on high chromium bricks is different.

Main high Chrome brick size:

Straight size:230×114×65 230×114×75 230×57×65

Split size: 230×114×32 230×114×40 230×114×25 230×114×50

Arch/Wedge size: 230×114×65/45 230×114×65/55 230×114×75/45 230×114×75/55 230×114×75/65

Tile size: 230×230×38 230×230×50 230×230×65 230×230×75

Other size: Key brick, Skew brick, Soap, Checker, Neck, Taper

Also produce high chrome bricks according to customers' needs

China refractory manufacturer low price high chrome brick for rock wool and glass fiber furnace

1.The high chrome brick Production Process

Crushing→Mixing→Shaping→Drying→Firing→Inspection→Packaging and Shipment

The high chrome bricks use α-Al2O3 as raw material, adding appropriate amount of chrome oxide powder and fine chromium corundum clinker powder, after forming, sintering at high temperature. The chrome oxide content of sintered chrome rigid brick is generally lower than that of fused-cast chrome corundum brick. It can also be prepared by the slurry casting method. The α-Al2O3 powder and the chrome oxide powder are uniformly mixed, and the glue and organic binder are added to make a thick slurry. At the same time, part of the chrome corundum clinker is added, and the brick is made by the grouting method. Fire again. It can be used as glass kiln lining, wire drawing glass flow hole cover tile and as back lining for hot metal pretreatment device, garbage incinerator, coal water slurry pressurized gasifier, etc.

High chrome brick usage:

High chrome brick usage:

High chrome bricks are mainly suitable for working linings of related reducing atmosphere industrial furnaces such as coal water slurry pressurized gasifiers.

The operating temperature has a great influence on the service life of high chrome bricks. The higher the temperature, the greater the damage rate and the lower the service life of the bricks. In the working environment of the coal water slurry gasifier, it will be reduced or significantly reduced due to the high temperature. The essential reason for the service life of high chrome bricks is that high temperature changes or significantly changes the viscosity-temperature characteristics of cinders. The higher the temperature, the lower the viscosity and the better the fluidity. The more serious the erosion and penetration of the bricks, the more erosion rate. The greater the life expectancy.

China refractory manufacturer low price high chrome brick for rock wool and glass fiber furnace

Packaging for high Chrome brick

1.Pallet+Paper or Steel angle bead+Paper board +Plastic or Steel belt +Plastic film

(1)Wooden pallet size:Usually0.92*0.92m(standard brick),but 1*1m (special shape brick) at most,

(2)Load weight of each pallet:Usually 1.5-1.7Tons, max 2.0 Tons.

(3)20 Foot Container can be loaded max 25-26Tons, about 13-16Pallets.

2.Can make the package according to customer's requirements.

Shipping for high Chrome brick

1.FEDEX/DHL/UPS/TNT for samples.

2.By Sea for batch goods.

3.Customers specifying freight forwarders or negotiable shipping methods!

4.Delivery Time of high Chrome brick:

(1)Samples:3 days for common shape samples;15 days for special shape samples.

(2)Batch goods:Within 7-10 days for in stock high chrome bricks from ordering shipping space to deliver goods and within 20-30 days for NO in stock high chrome bricks.

High Chrome Brick Payment Terms

(1)T/T, Western Union,LC;

(2)Usually 30% deposits,70% balance to be paid before delivery or against copy of BL or negotiations

Others

1. MOQ: Usually 1 container, MOQ 1Tons, Customers can order certain PCS for special high chrome brick.

China refractory manufacturer low price high chrome brick for rock wool and glass fiber furnace

High alumina brick

Corundum Brick

High Alumina Castable

Jerry Li

Cell&WhatsApp: 0086-13373957739

Email: jerry(at)firebricks-supplies.com

|

|

Customized Size White Bricks for Open Hearth Furnace and Industrial Applications Images |